Short Circuit Coordination

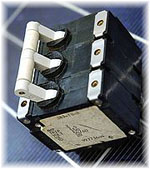

Circuit breakers and fuses come with an overcurrent rating (or size), and a short circuit interrupting rating. The overcurrent rating specifies the amount of electrical current the device should tolerate without the fuse blown, or circuit breaker tripping. The short circuit rating is the maximum electrical current the device can tolerate before it fails.

Circuit breakers and fuses come with an overcurrent rating (or size), and a short circuit interrupting rating. The overcurrent rating specifies the amount of electrical current the device should tolerate without the fuse blown, or circuit breaker tripping. The short circuit rating is the maximum electrical current the device can tolerate before it fails.

Consider, for example, a 100 amp circuit breaker. At some value of current exceeding 100 amps, you would expect the breaker to trip. If 150 amps passes through the breaker for a certain period of time, it should trip. But what happens if 20,000 amps flow thru the device? Will the breaker trip or explode? The answer depends largely on the manufacturer’s short circuit interrupting rating for that device. If the short circuit rating was 30kA, it should trip, while a 14kA rated breaker would very likely explode. The short circuit study examines this for you. Fault levels are calculated at points throughout the system and compared to the short circuit interrupting ratings of the devices used at each location.

A Short Circuit Coordination Study is critical for the safe, efficient and economical operation of any electrical distribution system. A Short Circuit Study will help to ensure that personnel and equipment are protected by establishing proper interrupting ratings of protective devices (circuit breaker and fuses). If an electrical fault exceeds the interrupting rating of the protective device, the consequences can be devastating, including injury, damaged electrical equipment and costly downtime.

A Coordination Study maximizes power system selectivity by isolating faults to the nearest protective device, as well as helping to avoid nuisance operations that are due to transformer inrush or motor starting operations.

A Coordination Study maximizes power system selectivity by isolating faults to the nearest protective device, as well as helping to avoid nuisance operations that are due to transformer inrush or motor starting operations.

A Short Circuit and Coordination Study is a very important, yet sometimes overlooked step after the initial design and before the implementation of an electrical distribution system. The NEC addresses the importance of this type of study in articles 110-9, 110-10, 240 and 517.17. It is clear that a third party, independent study performed during/after the equipment submittal process, can prove to be invaluable. A Short Circuit and Coordination Study serves to incorporate all the system changes that come about after the initial design. Some examples of factors that commonly change in the implementation of a system are: the utility available fault level, size and /or transformer impedance values, conductor size/type, addition of motors and the system operating parameters.

For more information on short circuit coordination, click here to contact a representative from one of our offices.